Valve Reconditioning and Valve Lapping and Leak Testing

Valve Reconditioning

One of the most common jobs during engine overhaul is grinding the valves. The equipment used should preferably be a wet valve grinder. With this type of machine, a mixture of soluble oil and water is used to keep the valve cool and carry away the grinding chips.

Like many machine jobs, valve grinding is mostly a matter of setting up the machine. The following points should be checked or accomplished before starting a grind. True the stone by means of a diamond nib. The machine is turned on, and the diamond is drawn across the stone, cutting just deep enough to true and clean the stone. Determine the face angle of the valve being ground, and set the movable head of the machine to correspond to this valve angle. Usually, valves are ground to the standard angles of 30° or 45°. However, in some instances, an interference fit of 0.5° or 1.5° less than the standard angle may be ground on the valve face.

The interference fit is used to obtain a more positive seal by means of a narrow contact surface. [Figure 1] Theoretically, there is a line contact between the valve and seat. With this line contact, the load that the valve exerts against the seat is concentrated in a very small area, thereby increasing the unit load at any one spot. The interference fit is especially beneficial during the first few hours of operation after an overhaul. The positive seal reduces the possibility of a burned valve or seat that a leaking valve might produce. After the first few hours of running, these angles tend to pound down and become identical.

|

| Figure 1. Interference fit of valve and valve seat |

Notice that the interference angle is ground into the valve, not the seat. It is easier to change the angle of the valve grinder work head than to change the angle of a valve seat grinder stone. Do not use an interference fit unless the manufacturer approves it.

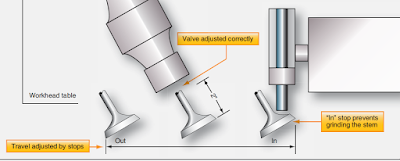

Install the valve into the chuck, and adjust the chuck so that the valve face is approximately 2 inches from the chuck. [Figure 2] If the valve is chucked any further out, there is danger of excessive wobble and also a possibility of grinding into the stem.

|

| Figure 2. Valve installed in grinding machine |

There are various types of valve grinding machines. In one type, the stone is moved across the valve face; in another, the valve is moved across the stone. Whichever type is used, the following procedures are typical of those performed when refacing a valve.

Check the travel of the valve face across the stone. The valve should completely pass the stone on both sides, yet not travel far enough to grind the stem. There are stops on the machine that can be set to control this travel.

With the valve set correctly in place, turn on the machine and the grinding fluid so that it splashes on the valve face. Back the grinding wheel off all the way. Place the valve directly in front of the stone. [Figure 3] Slowly bring the wheel forward until a light cut is made on the valve. The intensity of the grind is measured by sound more than anything else. Slowly draw the valve back and forth across the stone without increasing the cut. Move the work head table back and forth using the full face of the stone, but always keep the valve face on the stone. When the sound of the grind diminishes, indicating that some valve material has been removed, move the workhead table to the extreme left to stop rotation of the valve. Inspect the valve to determine if further grinding is necessary. If another cut must be made, bring the valve in front of the stone, then advance the stone out to the valve. Do not increase the cut without having the valve directly in front of the stone.

|

| Figure 3. Valve in chuck ready to grind |

An important precaution in valve grinding, as in any kind of grinding, is to make light cuts only. Heavy cuts cause chattering, that may make the valve surface so rough that much time is lost in obtaining the desired finish.

After grinding, check the valve margin to be sure that the valve edge has not been ground too thin. A thin edge is called a feather edge and can lead to preignition; the valve edge would burn away in a short period of time, and the cylinder would have to be overhauled again. Figure 4 shows a valve with a normal margin and one with a feather edge.

|

| Figure 4. Engine valves showing normal margin and a feather edge |

The valve tip may be resurfaced on the valve grinder. The tip is ground to remove cupping or wear, and also to adjust valve clearances on some engines.

The valve is held by a clamp on the side of the stone. [Figure 5] With the machine and grinding fluid turned on, the valve is pushed lightly against the stone and swung back and forth. Do not swing the valve stem off either edge of the stone. Because of the tendency for the valve to overheat during this grinding, be sure plenty of grinding fluid covers the tip.

|

| Figure 5. Grinding a valve tip |

Grinding of the valve tip may remove, or partially remove, the bevel on the edge of the valve. To restore this bevel, mount a V-way approximately 45° to the grinding stone. Hold the valve onto the V-way and twist the valve tip onto the stone. With a light touch, grind all the way around the tip. This bevel prevents scratching the valve guide when the valve is installed.

After the grinding procedure is finished, it is sometimes necessary that the valve be lapped to the seat. This is done by applying a small amount of lapping compound to the valve face, inserting the valve into the guide, and rotating the valve with a lapping tool until a smooth, gray finish appears at the contact area. The appearance of a correctly lapped valve is shown in Figure 6.

Valve Lapping and Leak Testing

After the grinding procedure is finished, it is sometimes necessary that the valve be lapped to the seat. This is done by applying a small amount of lapping compound to the valve face, inserting the valve into the guide, and rotating the valve with a lapping tool until a smooth, gray finish appears at the contact area. The appearance of a correctly lapped valve is shown in Figure 6.

|

| Figure 6. A correctly lapped valve |

After the lapping process is finished, be sure that all lapping compound is removed from the valve face, seat, and adjacent areas. The final step is to check the mating surface for leaks to see if it is sealing properly. This is done by installing the valve in the cylinder, holding the valve by the stem with the fingers, and pouring kerosene or solvent into the valve port. While holding finger pressure on the valve stem, check to see if the kerosene is leaking past the valve into the combustion chamber. If it is not, the valve re-seating operation is finished. If kerosene is leaking past the valve, continue the lapping operation until the leakage is stopped. The incorrect indications are of value in diagnosing improper valve and valve seat grinding. Incorrect indications, their cause, and remedy are shown in Figure 7.

|

| Figure 7. Incorrectly lapped valves |

Post a Comment